Aussie Iron Man: Patient receives a 3D-printed titanium jaw

A Melbourne psychologist has taken a step towards becoming an Aussie Iron Man, after receiving a 3D-printed prosthetic jaw in May.

In an Australian-first operation, surgeons, academics and a local 3D-printing company collaborated to produce the customised titanium implant.

The patient, 32-year-old Richard Stratton, told Mashable Australia the journey began when doctors discovered he lacked a condyle — a portion of bone that connects the skull to the jaw — on the left-hand side of his jaw. Doctors haven’t been able to work out how the deformity started, but it meant the right-hand side of his face was doing all the work.

The journey to a 3D-printed jaw

As Stratton’s jaw pain grew over the last few years, his doctor came to him with the idea of implanting a 3D-printed jaw joint.

Nigel Finch, chairman of Melbourne-based company 3D Medical, told Mashable Australia Stratton’s surgical team reached out to the company as they wanted a prosthetic that best suited the patient’s unique jaw.

Richard Stratton before the surgery.

Image: Richard Stratton

In other cases, a standard prosthetic is chosen that’s the nearest match to the patient’s size and shape, Finch said. Surgical work is then done to change the anatomy of the patient to fit the implant. Computer generated manufacturing, on the other hand, means the implant is fitted precisely to the patient’s body.

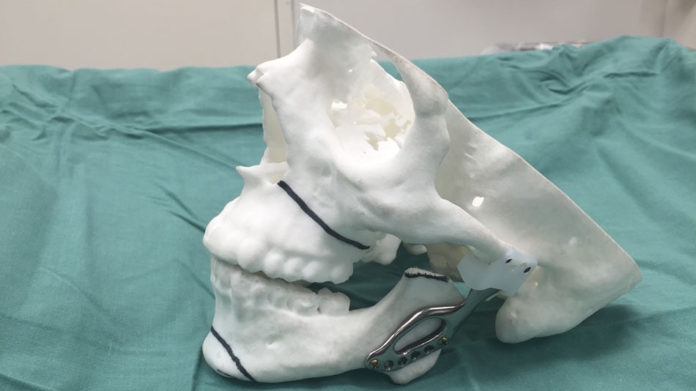

Working off medical imaging data, 3D Medical were able to build a model of Stratton’s skull and jaw in virtual reality using image processing and rendering software. After numerous tests over a month-long period, the company printed the titanium implant to meet all medical standards. “It’s made in an incredibly fine level of detail that we were able to achieve using a 3D printer,” Finch said.

Because the patient’s jaw did not need to be altered to fit a standard-sized prosthetic, the surgery time was shortened. In a single procedure over five hours on May 2 at Epworth Freemason hospital in East Melbourne, the jaw was opened and the implant inserted, Finch said.

The idea of customisation also meant a lot to Stratton. “Knowing it was something purposefully made for me, not just something off the shelf … it felt like they’d really studied my skull and made it specifically for me,” he said.

The results

Stratton said he’s very happy with the results of the surgery. There’s been some swelling and tightness, but six weeks on, it’s calming down and his face is looking more symmetrical than previously. “I’m happy. I’ve always been conscience of my tilted smile,” he added.

While he was nervous about the procedure, the enormity of the medical and technological feat has started to sink in. “I was glad I could be a part of that pioneering moment,” he said. “The technology will continue to grow. I can’t wait to see what they do with other prosthetics.”

“I’ve got something 3D printed in me. How many people can say that right now?”

Richard Stratton recovering from his surgery.

Image: Richard Stratton

The future of 3D-printed prosthetics

3D Medical are planning to use 3D printing to produce medical implants in all shapes and sizes for different parts of the body. “This particular operation has validated our business model,” Finch said.

In the future, he hopes the time between when an implant is required and when it is delivered will be drastically reduced. One day, implants could be printed on-demand using standard medical imaging data from procedures like magnetic resonance imaging (MRIs), X-rays and ultrasounds, he said. Most importantly, implants could be constructed to ideally suit the patient’s anatomy.

3D printing prosthetics is not an expensive process and will only get cheaper as the technology is leveraged, Finch added. However, he suggested companies like his need to work with the hospital system, health insurers and surgical teams to demonstrate the efficacy of the system.

“The test here is who pays for it?” he said. “There’s a lot of inertia around how these procedures are done … It’s just going to take time for the healthcare system to start to look at that and bring it into the mainstream.”

Have something to add to this story? Share it in the comments.