While 3D printing has already been used to create entire body parts, printers that can extrude living cells are still very expensive. Clinical researchers at the Feinstein Institute for Medical Research in Manhasset, NY, a part of North Shore-LIJ Health System, have partnered with folks from MakerBot to use off-the-shelf 3D printers to create personalized functional tracheas for needy patients.

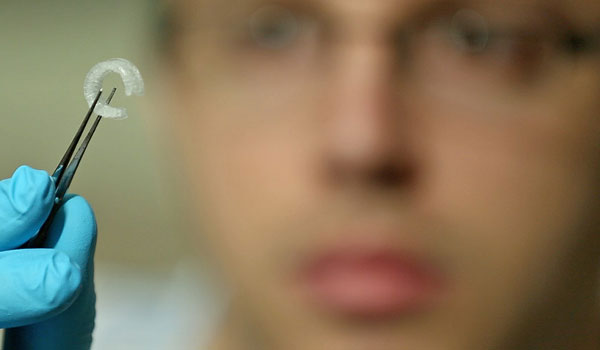

The team decided to try using MakerBot’s standard PLA Filament, a resin made from sugar corn, as a scaffold to grow the cartilage tissue. The team built a bunch of windpipe models, taking them to North Shore-LIJ surgeons that specialize in trachea surgeries for evaluation. After repeated changes and modifications, they had created more than 100 versions of the trachea within about a month. Because the printing process involves heating up the PLA Filament, it automatically comes out sterilized and ready for the next step

Pressing forward, they used a modified MakerBot Replicator 2X Experimental 3D printer that has two extruders to apply a “bio-ink” full of living cells onto the scaffold. Placing the resulting trachea into a bioreactor allows it to promote cellular growth over the scaffold in preparation for implantation.

Here’s a video about the project:

Flashbacks: Artificial Windpipe Seeded With Patient’s Stem Cells Implanted for First Time…; World’s First Artificial Trachea Transplant Patient Gets Successor…; First Artificial Trachea Implants Breathe Life into Tissue Engineering…; Surgically Implanted 3D-Printed Tracheal Splint Saves Baby’s Life…

More from MakerBot: A New Frontier in Tracheal Repair

Press release: Using 3D Printing, MakerBot and The Feinstein Institute for Medical Research Create Cartilage to Repair Tracheal Damage…

The post Clinicians Building Tracheas Using Off-The-Shelf 3D Printers (VIDEO) appeared first on Medgadget.